Offices

Internal Design and Simulation Technical Office

In our technical office we develop and design our moulds and our trimming tools.

Through the experience of our technicians, we can develop the cast part

starting from the machining 3D drawing or 3D model of the product. We prepare

the layout of the equipment to be submitted and discussed with the customer

We develop and complete the 3D and 2D mould design to be used for construction.

-

We use the following equipment

- N. 5 2D-3D Cad stations

- Systems used: Catia V5, Unigraphics, Pro-Engineering, Powershift

- N. 1 Castle Mind station

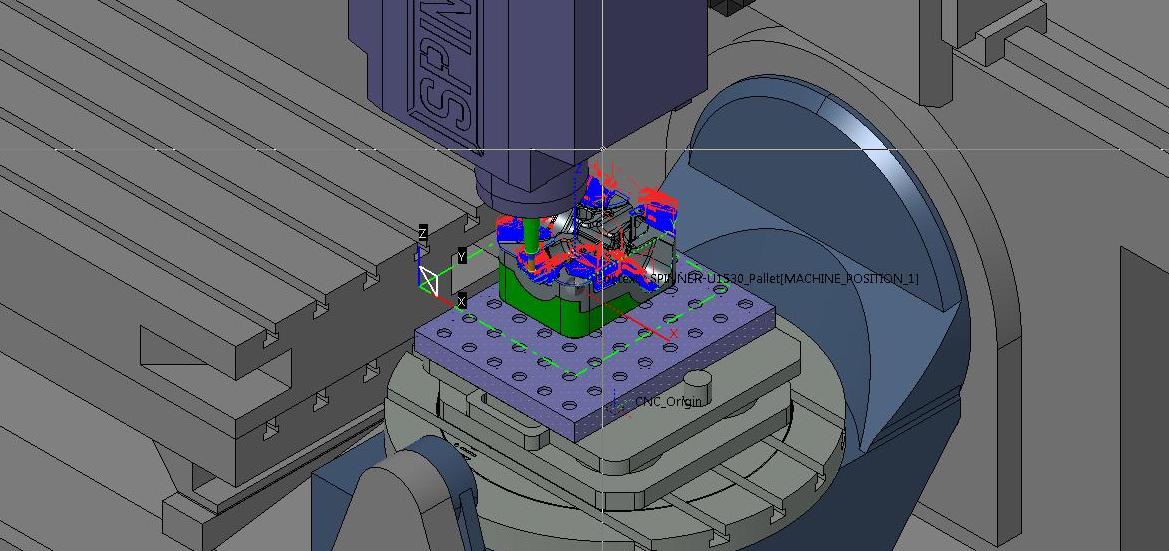

CAM Office

In our production department we use 7 CAM stations with which we prepare the machines path where we manufacture electrodes, cavities, sliders, inserts pins etc. The machines path is for milling, drilling and turning. All our operators in charge of machining department are able to use the following softwares: Worknc and Delcam.

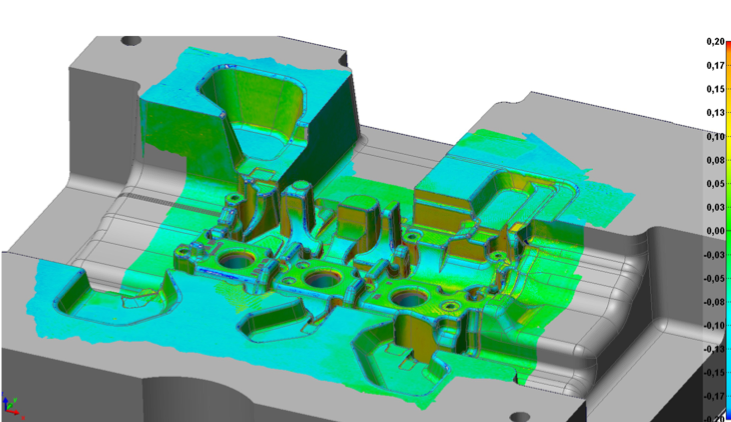

Mould parts scanner area

In our production department we have set up an area where, through a laser scanner and an optical scanner, we verify and superimpose the most delicate parts of the mould with the 3D model of the mould:

- The graphite electrodes (before sending them to the EDM department)

- All parts in contact with aluminum (cavities,sliders, inserts etc) before sending them to the assembly department

Once the control activity is over, if the parts are in tolerance determined by us, we move on to the following department otherwise the parts return to work in order to correct any errors during the construction phase.

Production department

In our production department (3,000 square meters) we manufacture our equipments with the latest generation machinery and with highly qualified operators.

- N. 9 high speed machining centers 4-5-6 continuous axes with maximum stroke 1600 x 1200

- N. 6 3-4 axis machining centers with maximum strokes 3000 x 1500 (N. 2 with deep drilling units)

- N. 4 CNC edm erosions

- N. 2 wire erosions

- N. 3 radial drills machines

- N. 1 Millutensil press for moulds spotting up to 2500x2500 (mould max weight 60 tons)

- N. 4 parallel lathes (N.2 with automatic CNC)

- N. 3 grinding machines

- N. 7 stations for mould assembly and spotting

- N. 1 “FARO” laser arm for mould parts cavity scanning

- N. 1 ATOS GOM optical scanner for cavity scanning before assembly

- N. 3 15 Ton bridge cranes

- N. 1 20+20 Ton bridge crane

List of our production structure:

List of our production structure: