Our work

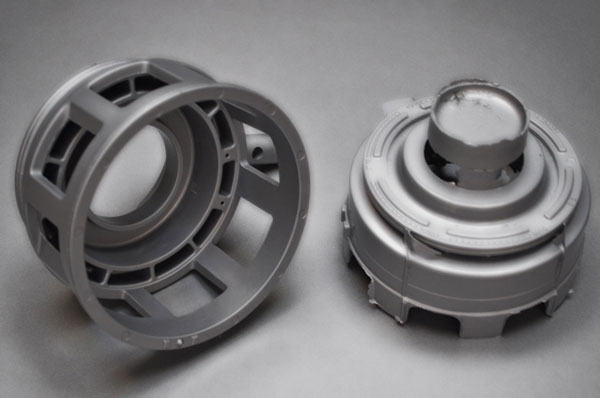

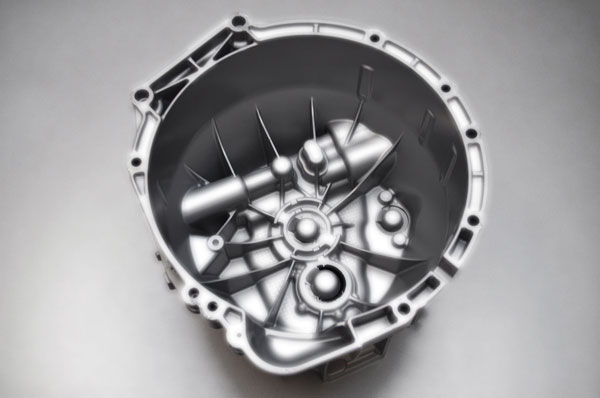

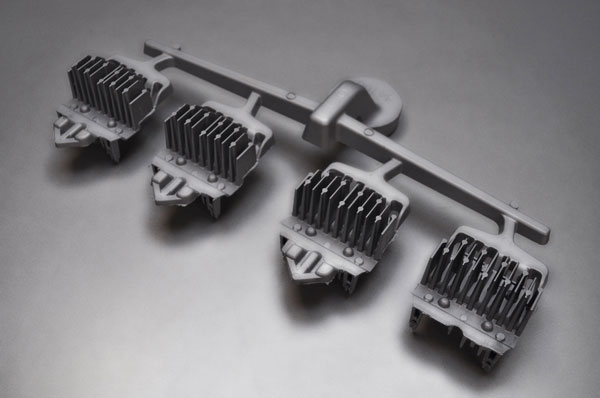

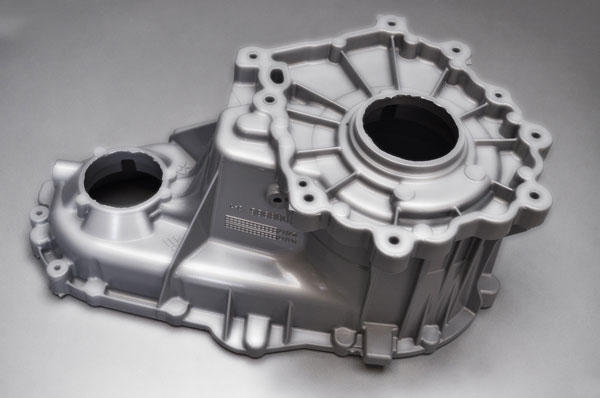

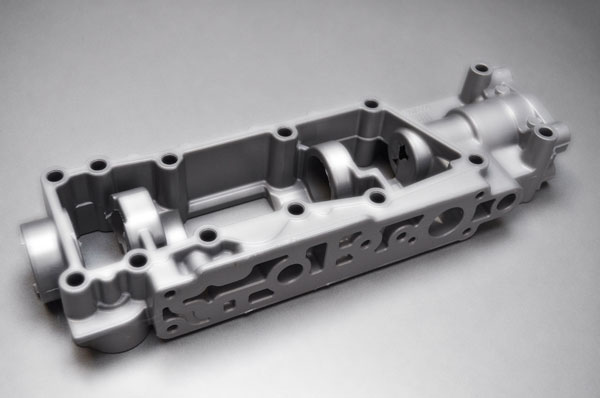

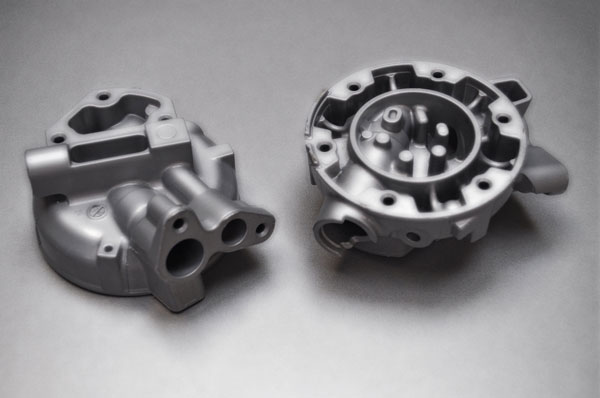

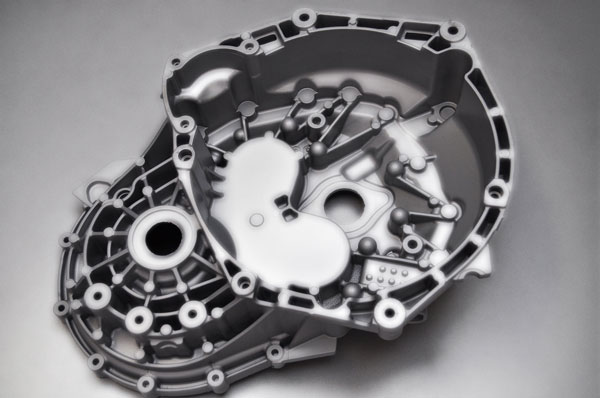

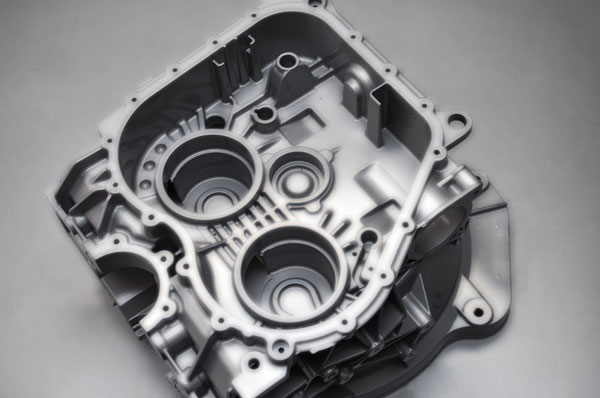

With more than 30 years of activity, we have been able to grow and gain experience in various sectors and applications: since the beginning,we have dedicated most of our production capacity to the automotive (90%), electronics and lighting sectors

Thanks to a targeted investment policy in new machinery (updated year by year through the insertion of new equipments) and careful staff training, we have had constant growth which today allows us to deal with different types of markets thanks to a workforce of 40 people active in our company as well as selected suppliers who help us supply quality moulds. With all this, we have 180.000 hours / year to use in the design and construction of our equipments.

We serve customers in Italy, Europe, North and South America and North Africa.

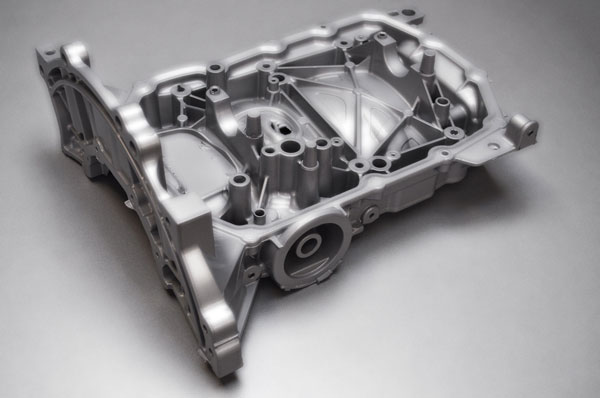

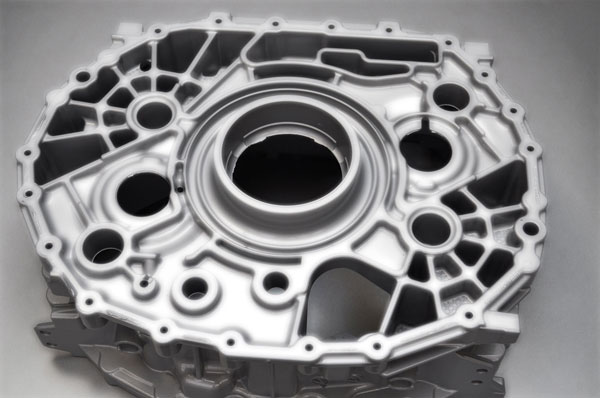

Our foundry services:

- Modeling and engineering on the parts to be made.

- Moulds and trimming design with 2D-3D CAD systems.

- Mould construction up to the 3.500 Ton machine.

- Experience in the use of technologies such as vacuum, squeeze and jet-cooling.

- Construction of trimming tools with double effect and hydraulic movements up to the 150 Ton press.

- Possibility of sampling and pre-production of our equipment up to the 3,200 Ton die casting machine.

- Possibility of carrying out CMM 2d-3d dimensional measurements on sampling casts.

- Assistance and rapid spare parts service on our equipment.